Start-up creates the world’s only 3D printer for implant-grade silicone. Prayasta has also developed a patented technology to make breast implants leak-proof and sutureable. The company will collaborate with IISc to help the medical sector develop customized soft tissue implants.

- Prayasta’s specialized 3D printing technology, Silimac, allows the printer to instantly make implants made of implant-grade silicone, all within the hospital.

- Start-up creates the world’s only 3D printer for implant-grade silicone and has developed technology to stop leakages from breast implants.

- Prayasta has also developed a patented technology that allows them to make breast implants that are leak-proof and sutureable, thereby reducing the risk of leakage and post-implantation displacements.

- Silimac technology has been adapted for making breast implants, but it can also be used to make other soft tissue implants such as those for the ears, chin, mouth, and tracheobronchial.

- Prayasta will collaborate with IISc to help the medical sector in the country develop customized soft tissue implants and skills that will enable them to develop 3D printing technologies faster.

Prayasta’s specialized 3D printing technology, Silimac, allows the printer to instantly make implants made of implant-grade silicone, all within the hospital.

Start-up creates the world’s only 3D printer for implant-grade silicone and has developed technology to stop leakages from breast implants.

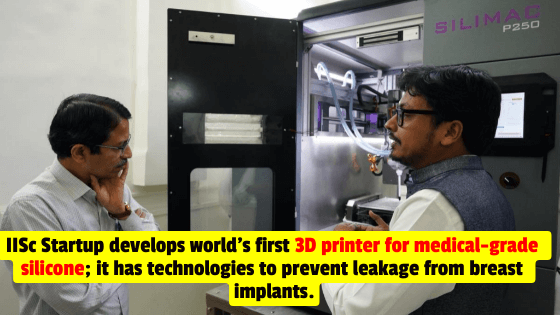

Prayasta co-founder Vikas Garg discusses how they are developing the world’s only 3D printer for implant-grade silicone in hospitals. Dr. Navkanta Bhat, IISc, deans the lecturer in Biomedical Engineering and Physiology at IISc, Bengaluru on November 10, 2022.

Prayasta, based in Bengaluru, India, has developed the first 3D printer for implant-quality silicone, which is currently being tested at BioSystems Science and Engineering (BSSE).

Prayasta’s specialized 3D printing machine, Silimac, can precisely design and print implant-grade silicone materials that a surgeon will use in his hospital. 3D printers allow surgeons to make very precise implants, which greatly improves the surgical outcomes for patients. They also reduced the time required to create implants by using conventional techniques.

3D prints of silicone implants are created using specialized equipment called Silimac, which allows it to be personalized in terms of shape, size, and contour. They can be made to have a specific weight, stiffness, and feel. It is as though you are getting a customized product.

Prayasta has also developed a patented technology that allows them to make breast implants that are leak-proof and sutureable, thereby reducing the risk of leakage and post-implantation displacements. Silimac technology has been adapted for making breast implants, but it can also be used to make other soft tissue implants such as those for the ears, chin, mouth, and tracheobronchial. In addition, prostheses can be attached to soft tissues.

An agreement with the partner was signed to begin working on this partnership.

Prayasta will collaborate with IISc to help the medical sector in the country develop customized soft tissue implants and skills that will enable them to develop 3D printing technologies faster.