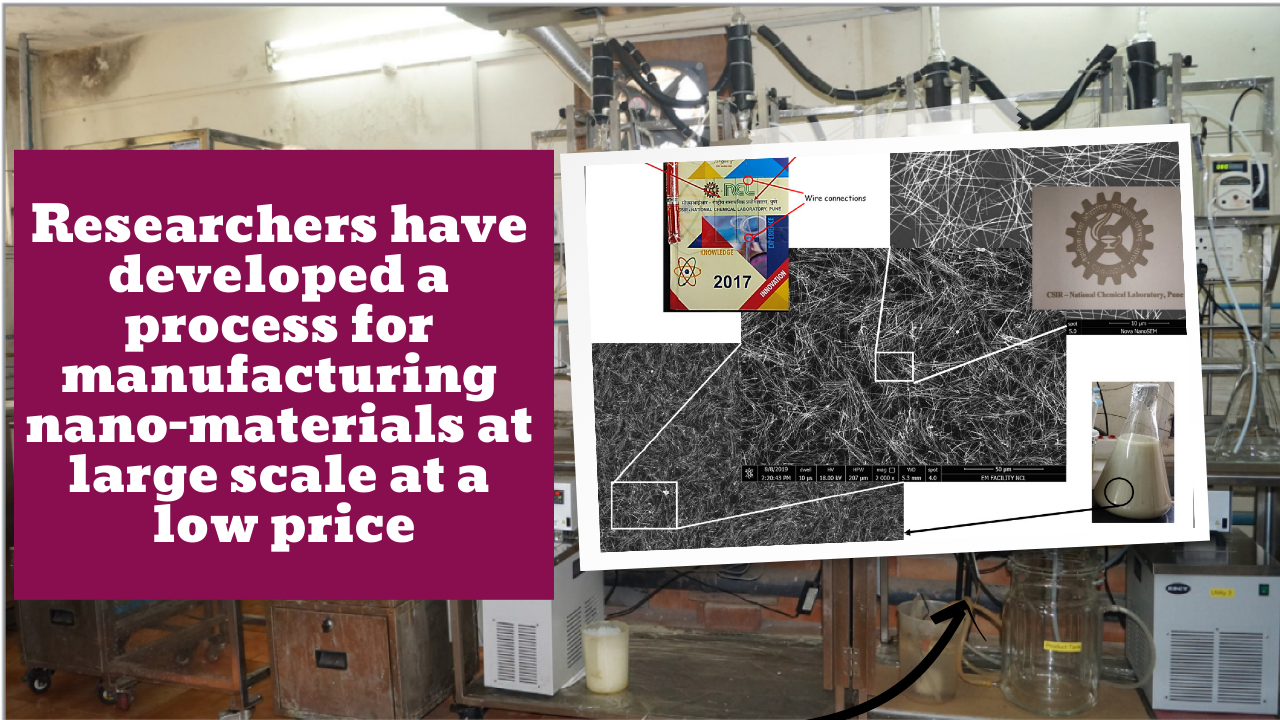

For large-scale manufacturing of nanomaterials (Silver nanowires), an Indian team of scientists and students has developed a technology that reduces prices to less than one-tenth of the market price. A total of five patent applications have been made for the new technology, including two each in the United States and abroad. Nanorbital Advanced Materials LLP (Ahmedabad) received the process technology license from CSIR-NCL in November 2020. This new nanomaterial will be tested for transparent conducting applications and printing flexible electronics, including wearable electrodes. Dr. Amol hopes to do this.

Key Highlight:

- An Indian team of scientists and students have developed a technology that can reduce prices to one-tenth of the market price for large-scale manufacturing of nanomaterials (Silver nanowires)

- The process has a temperature of over 130 degrees Celsius (Fahrenheit)

- It was licensed to Nanorbital Advanced Materials LLP (Ahmedabad) in November 2020, and three more industries signed material transfer agreements in 2021 by the CSIR-NCL.

- This new nanom material will be tested for transparent conducting applications and printing flexible electronics, including wearable electrodes.

For large-scale manufacturing of nanomaterials (Silver nanowires), an Indian team of scientists and students have developed a technology that can reduce prices to one-tenth of the market price for large-scale manufacturing of nanomaterials (Silver nanowires).

It isn’t easy to create vast amounts of one-dimensional nanomaterials like nanowires, nanotubes, etc., making them an expensive commodity. It is critical for touch screens and other conducting coating applications to have a homogeneous nanowire diameter range with small length variations.

CSIR-National Chemical Laboratory, Pune’s Dr. Amol A. Kulkarni devised a technology that can create silver nanowires at 500 grams per day for 20 cents per gram, as opposed to the 250 cents/gm to 400 cents/gm market pricing.

Using the Department of Science and Technology’s Advanced Manufacturing Technologies Program, it is possible to manufacture functional nanomaterials (silver nanowires) on a large scale at a reasonable cost.

Silver nanowires with high conductivity were produced as part of the process, and these nanowires can be used in display technologies and flexible electronics to make conducting inks and coatings. A total of five patent applications have been made for the new technology, including two each in the United States and abroad.

With this approach, we have developed the first continuous method for synthesizing functional nanomaterial (Silver nanowires) at a cheap cost (20$/gm) and with good product quality (aspect ratio of nanowires >1000). Compared to existing batch manufacturing techniques, which yield large amounts of nanoparticles in suspension that are difficult to separate from nanowires, this method is a straightforward, cost-effective, and scalable synthesis route. It has been tested at the characterization facility of CSIR-NCL and is now in stage 8 of the Technology Readiness Level.

It was licensed to Nanorbital Advanced Materials LLP (Ahmedabad) in November 2020, and three more industries signed material transfer agreements in 2021 by the CSIR-NCL. Doctor Amol aims to test the created nanomaterial in a variety of display devices for transparent conducting applications and print flexible electronics, including electrodes that may be worn.

A technological breakthrough in electronic chemicals may eventually lead to new job opportunities for the Indian industry.

The process has a temperature of over 130 degrees Celsius (Fahrenheit). In the series of four Multistage Multiphase reactors, reactants are preheated and supplied to utilities connected to the reactors for accurate temperature control. Condensers are mounted on top of the reactors and are used to collect the condensed reaction vapors. After passing through four multiphase reactors, the reactant mixture is cooled, collected, and delivered for further purification at the fourth multiphase reactor’s outlet in the product tank.

A process developed by Dr. Amol A. Kulkarni from @csir_ncl , can produce silver nanowires at the scale of 500 grams per day at the cost of 20$/gm when compared to 250$/gm to 400$/gm of market price.

— DSTIndia (@IndiaDST) November 1, 2021

Dr Shekhar Mande, DG CSIR inaugurated the pilot plant for continuous flow manufacture of Silver Nanowires at CSIR-NCL @csir_ncl @CSIR_IND @shekhar_mande @AshwiniNangia pic.twitter.com/RhhDuy7XFI

— Prabhakar Ingle (@PKIngle) January 31, 2020

Continuous & scalable process for manufacturing precision Silver Nanowires developed at #CSIR-NCL. It is demonstrated at scale of 500 gm/day & can be scaled up to 5 kg/day & further. https://t.co/0cqAHlostO

— NCL Innovations (@nclinnovations) January 7, 2020

IP: WO2019049172, IN201711031533@csir_ncl @PremnathV6 @shekhar_mande pic.twitter.com/jid775BjGi

[…] NCL Researchers have developed a low-cost process for large-scale manufacturing of… […]