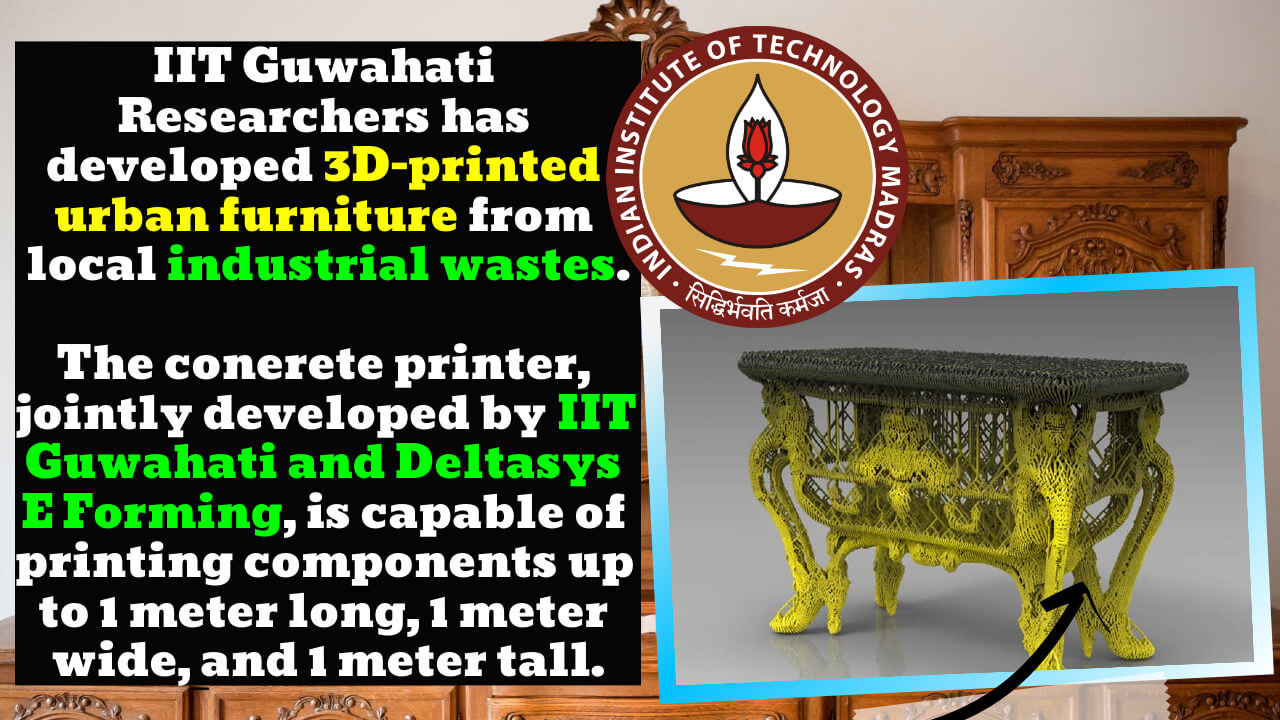

People in the building and construction industries are starting to use 3D printing to make concrete. IIT Guwahati and Deltasys E Forming worked together to make a concrete printer. It can make parts up to 1 meter long, 1 meter wide, and 1 meter tall.

Key Highlight:

- Three IIT Guwahati researchers have designed 3D-printed urban furniture utilizing local industrial trash.

- IIT Guwahati researchers Dhrutiman Dey, Dodda Srinivas, and Bhavesh Chaudhari have discovered new 3D printable cementitious mix compositions.

- Developed collaboratively by IIT Guwahati and Deltasys E Forming, the concrete printer can print components up to 1 m long, 1 m wide, and 1 m tall.

- The 3D-printed urban furniture cycle takes roughly 20 minutes.

- The IIT Guwahati research group used 3D-printed furniture with a seating height of o.4 meters, a width of o.4 meters, and arch-shaped support modeled and sliced using SolidWorks and Simplify3D.

Three IIT Guwahati researchers have designed 3D-printed urban furniture utilizing local industrial trash. IIT Guwahati researchers Dhrutiman Dey, Dodda Srinivas, and Bhavesh Chaudhari have discovered new 3D printable cementitious mix compositions. Developed collaboratively by IIT Guwahati and Deltasys E Forming, the concrete printer can print components up to 1 m long, 1 m wide, and 1 m tall The 3D-printed urban furniture cycle takes roughly 20 minutes. It is becoming more used in the building and construction industries. Recently developed 3D-printed modular homes, pedestrian footbridges, business buildings, public schools and low-cost toilet units have the potential to transform the construction industry. The IIT Guwahati research group used 3D-printed furniture with a seating height of o.4 meters, a width of o.4 meters, and arch-shaped support modeled and sliced using SolidWorks and Simplify3D. The entire unit was printed layer by layer at 80 mm/s with a 10 mm layer height. After printing, the unit was covered with damp gunny bags for 7 days to cure.

These constructions were traditionally mold-cast, requiring additional concrete, labor, and formwork preparation. But 3D concrete printing uses less concrete and eliminates the need for a mold. “We showed how material-efficient structures can be generated in our lab-scale 3D printer,” stated Dr. Biranchi Panda of IIT Guwahati’s Mechanical Engineering Department. Our goal is to create high-performance concrete mixtures from industrial wastes for 3D printing.

[…] IIT Guwahati Researchers have developed 3D-printed urban furniture from local industrial trash. […]